necessary

Why is that necessary?

- CSR

- Recycling of carbide tools

- Why is that necessary?

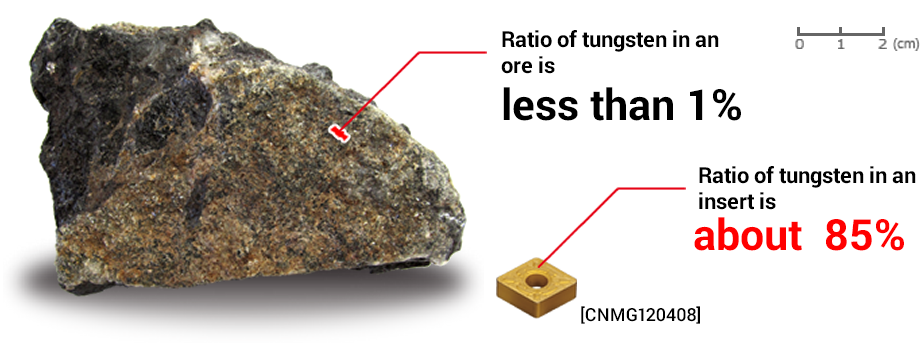

To extract tungsten from mineral, a process called “refining" is required, however, the ratio of tungsten in the mineral is less than 1%. On the other hand, tungsten content in a cemented carbide tool is approximately 85%. When the efficiency of refining is considered, you can easily understand that extracting it from cemented carbide scrap is much more “economical".

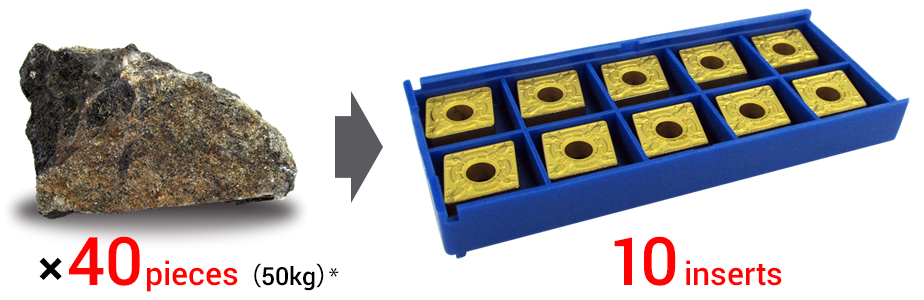

To make one insert, a volume of ores must be refined. Considering mining efforts and transportation energy, etc., you can see how economically it could be recycled from the cemented carbide scrap!

* Converted in 85% of content rate

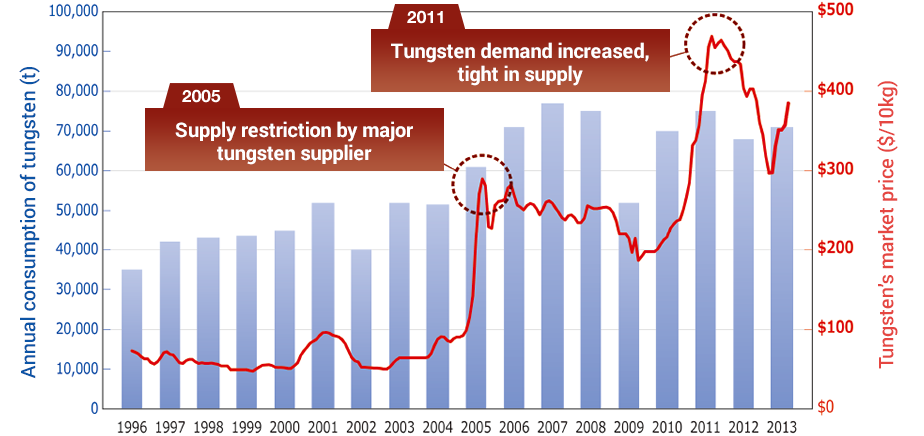

Sumitomo Electric Group is ready for recycling the total volume of domestic sales of the cemented carbides internally. Allocation of raw materials domestically leads to a stable price and supply of cemented carbide tools.