Grades Selection

Grades Selection

General Steel, Soft Steel

Coated Carbide

ACU2500

General-purpose grade supporting steel, stainless steel, and cast iron machining

Adopts a carbide substrate with excellent fracture resistance and wear resistance, plus a new coating with excellent wear resistance and chipping resistance, realising stable long tool life on various work materials

XCU2500

General-purpose grade for a wide variety of materials such as steel, cast iron and stainless steel

New coating combining wear and fracture resistance realises long tool life in medium-speed to high-speed machining

ACP2000

For high-speed machining of steel

Stable long tool life in high-speed machining is realised by adopting a tough carbide substrate and a new coating with excellent thermal crack resistance

ACP3000

Our 1st recommended grade for milling steel

Carbide substrate with excellent thermal crack resistance, plus a new coating with excellent wear resistance and chipping resistance, realises stable long tool life over a wide range of cutting conditions

Cermet

T2500A

For finishing of steel and stainless steel

Fine, uniform grain structure greatly improves toughness, realising long tool life and excellent surface finishes.

T4500A

For finishing of steel and stainless steel

Tough grade with excellent fracture resistance and reduced thermal cracking

Stainless Steel

Coated Carbide

AC6000M Series

AC6020M

Combines a high-hardness carbide substrate with excellent wear resistance and a new CVD coating with improved coating strength to achieve both excellent wear resistance and fracture resistance. Achieves long, stable tool life during high-speed cutting.

AC6030M

Our 1st recommended grade for turning of stainless steel, achieving long and stable machining. Drastically reduces the abnormal damage common in stainless steel machining, thanks to the improved coating strength and excellent adhesion.

AC6040M

Drastically improves reliability in the unstable cutting range, thanks to the excellent adhesion and peel-off resistance of the new PVD coating as well as the improved fracture resistance of the dedicated carbide substrate.

For Small Lathes

AC1030U

High-quality cutting edge grade suppresses adhesion and micro-chipping, realizing excellent machined surface quality.

Cermet

T1000A/T1500A

T1000A

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron.

T1500A

A general-purpose cermet made from hard grains with different grain sizes, delivering functionality that provides an excellent balance of wear resistance and toughness, along with good surface finish quality.

Cast Iron

Coated Carbide

AC4000K Series

AC4010K

Superior wear and plastic deformation resistant grade, that utilizes a high hardness carbide substrate coupled with the high hardness Super FF Coat for high speed to continuous turning of Cast Iron.

AC4015K

Our 1st recommended grade for ductile cast iron. New high-adhesion, high-strength CVD coating realises both wear resistance and chipping resistance.

AC420K

Superior fracture resistance, providing excellent stability in interrupted unstable cutting and when cutting mill-scaled work.

For Small Lathes

AC1030U

High-quality cutting edge grade suppresses adhesion and micro-chipping, realizing excellent machined surface quality.

Cermet

T1000A

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron.

Coated CBN

BNC8115/BNS8125

BNC8115

Grade with 100% solid CBN structure, using PVD coating with excellent wear resistance to enable roughing operations.

Uncoated CBN

BNS8125

Grade with 100% solid CBN structure that exhibits excellent wear and fracture resistance

Exotic Alloy

Coated Carbide

AC5000S Series

AC5005S

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining.

AC5015S

Our 1st recommended grade for turning exotic alloys as it realises stable tool life with high-speed, high-efficiency machining.

AC5025S

High-toughness grade for realising stable tool life for interrupted cutting machining or mill-scaled work.

Carbide

EH510

General-purpose grade for titanium machining that features excellent wear and thermal resistance. For applications from roughing to finishing.

EH520

Tough grade for titanium machining with excellent fracture and thermal resistance. Perfect for interrupted cutting and mill-scaled work.

Uncoated CBN

NCB100

Achieves high-efficiency, improved machining accuracy, and long tool life in machining of exotic alloys such as titanium alloy and Co-Cr alloys.

Hardened Steel

Coated CBN

BNC2115

High-precision grade realizing long tool life with excellent surface roughness and stable machining. Maintains excellent surface roughness thanks to a high notch-wear resistant coating and tough CBN substrate.

BNC2125

1st recommended grade, balancing excellent wear resistance and fracture resistance in hardened steel machining.Along with a tough CBN substrate, the coating combines wear resistance and toughness to achieve long, stable tool life even in high-efficiency and interrupted machining.

Uncoated CBN

BN1000/BN2000

BN1000

For high-speed machining, BN1000 provides the highest wear resistance of all uncoated SUMIBORON grades, improving fracture resistance while maintaining an emphasis on wear resistance.

BN2000

General-purpose grade for general hardened steel machining with a high degree of fracture and wear resistance.

Cemented Carbides and Hard Brittle Materials

PCD

NPD10

100% diamond that directly binds nano-order diamond particles with high strength. Demonstrates optimum wear and fracture resistance as well as the best edge sharpness.

DA90

Coarse sintered diamond particles, with high diamond content for excellent wear resistance.

Powdered Mettal

Coated Carbide

AC5005S

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining.

Cermet

T1000A

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron.

Coated CBN

BN7115

Grade balancing ultimate cutting edge sharpness with fracture resistance, suitable for finishing of sintered alloy

BN7000

Grade exhibiting improved wear and fracture resistance in roughing of sintered materials.

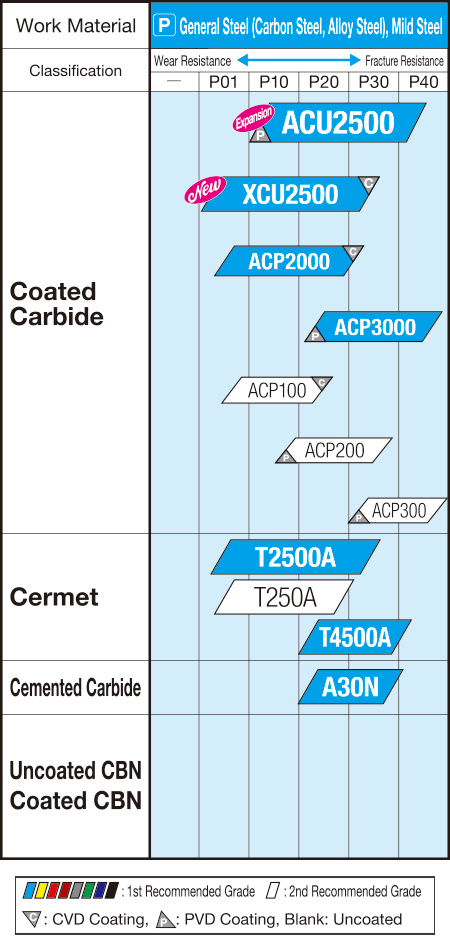

General Steel ,Mild Steel

Coated Carbide

ACU2500

General-purpose grade supporting steel, stainless steel, and cast iron machining

Adopts a carbide substrate with excellent fracture resistance and wear resistance, plus a new coating with excellent wear resistance and chipping resistance, realising stable long tool life on various work materials

XCU2500

General-purpose grade for a wide variety of materials such as steel, cast iron and stainless steel

New coating combining wear and fracture resistance realises long tool life in medium-speed to high-speed machining

ACP2000

For high-speed machining of steel

Stable long tool life in high-speed machining is realised by adopting a tough carbide substrate and a new coating with excellent thermal crack resistance

ACP3000

Our 1st recommended grade for milling steel

Carbide substrate with excellent thermal crack resistance, plus a new coating with excellent wear resistance and chipping resistance, realises stable long tool life over a wide range of cutting conditions

Cermet

T2500A

For finishing of steel and stainless steel

Fine, uniform grain structure greatly improves toughness, realising long tool life and excellent surface finishes.

T4500A

For finishing of steel and stainless steel

Tough grade with excellent fracture resistance and reduced thermal cracking

Stainless Steel

Coated Carbide

ACU2500

General-purpose grade supporting steel, stainless steel, and cast iron machining

Adopts a carbide substrate with excellent fracture resistance and wear resistance, plus a new coating with excellent wear resistance and chipping resistance, realising stable long tool life on various work materials

XCU2500

General-purpose grade for a wide variety of materials such as steel, cast iron and stainless steel

New coating combining wear and fracture resistance realises long tool life in medium-speed to high-speed machining

ACM100

For high-speed machining of stainless steel

Adopts high-hardness micro-grain carbide substrate and super multi-layered coating to realise outstanding wear resistance.

ACM200

For machining high-hardness stainless steel

Adopts newly developed high-strength cemented carbide with excellent wear resistance and thermal resistance, realizing outstanding stability when machining hardened stainless steel.

ACM300

Our 1st recommended grade for milling stainless steel

Adopts high-strength carbide substrate and super multi-layered coating for next-level wear resistance and fracture resistance.

Cermet

T2500A

For finishing of steel and stainless steel

Fine, uniform grain structure greatly improves toughness, realising long tool life and excellent surface finishe.

T4500A

For finishing of steel and stainless steel

Tough grade with excellent fracture resistance and reduced thermal cracking.

Cast Iron

Coated Carbide

ACU2500

General-purpose grade supporting steel, stainless steel, and cast iron machining

Adopts a carbide substrate with excellent fracture resistance and wear resistance, plus a new coating with excellent wear resistance and chipping resistance, realising stable long tool life on various work materials

XCU2500

General-purpose grade for a wide variety of materials such as steel, cast iron and stainless steel

New coating combining wear and fracture resistance realises long tool life in medium-speed to high-speed machining

XCK2000

For high-speed cast iron milling

Along with a high-hardness carbide substrate, the new coating combining wear and fracture resistance realises superb long tool life in medium-speed to high-speed machining

ACK2000

For high-speed cast iron milling

Stable long tool life with high-speed machining is realised by adopting a tough carbide substrate and a new coating with excellent thermal resistance.

ACK3000

Our 1st recommended grade for milling cast iron

Adopts a high thermal conductivity carbide substrate and a new coating with excellent wear resistance and chipping resistance, realizing stable long tool life over a wide range of cast iron machining operations.

Uncoated CBN

BN7000

Grade exhibiting wear and fracture resistance in cutting of cast iron and exotic alloys.

BNS8125

Grade with 100% solid CBN structure that exhibits excellent wear and fracture resistance

Coated CBN

BNC8115

Grade with 100% solid CBN structure, using PVD coating with excellent wear resistance to enable roughing operations

Exotic Alloy

Coated Carbide

ACU2500

General-purpose grade supporting steel, stainless steel, and cast iron machining

Adopts a carbide substrate with excellent fracture resistance and wear resistance, plus a new coating with excellent wear resistance and chipping resistance, realising stable long tool life with various work material grades.

Hardened Steel

CBN (SUMIBORON)

BN350

Grade with ultimate cutting edge strength, suitable for heavy interrupted cutting.

BN7000

Maximum CBN content for high resistance to both wear and breakage.

Non-Ferrous Metals

Sintered diamond (SUMIDIA)

Coated Carbide

DL2000

For milling non-ferrous metal, utilising DLC coat with a low coefficient of friction and excellent adhesion resistance

PCD

DA1000

High-density sintered material made of ultra-fine grain diamond that demonstrates optimum wear and fracture resistance and excellent edge sharpness.

Catalog

Catalog